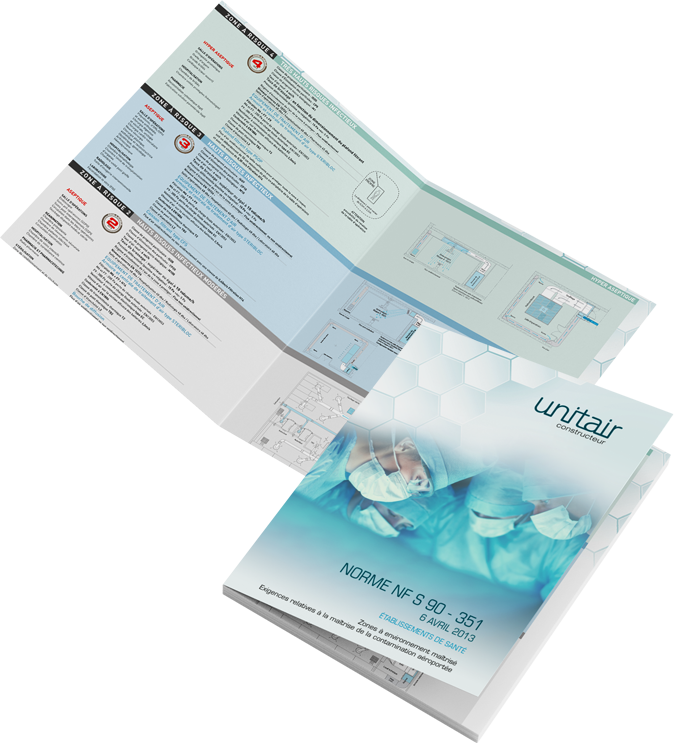

Standards

NFS 90-351

Healthcare establishments – Controlled environment zones – Requirements concerning the control of airborne contamination

- Level 4 Risk Zones - ISO 5

- Level 3 Risk Zone - ISO 7

- Level 2 Risk Zone - ISO 8

Very high risk of infection

- Particulate air cleanliness classification : ISO 5 (less than 100,000 particles of 0.1 micron per m³ of air)

- Particle elimination classification of 0.5 microns : CP5

- Microbiological cleanliness classification M1

Air treatment equipment

- STERIBLOC unit – Filtration F6 + F7 + F9 (in conformity with standard EN 1886)

- Distribution of treated air via filtering ceiling units

- Unidirectional air flow

- H14 finishing filters for the treated zone

- Rate of air turnover : depending on sizing of filtering ceiling unit

- Fresh air renewal in the room : 6 vol/h

- Pressurisation of the room : 15 Pa (differential fresh air / recycled air)

- Air temperature (except for specific requirements) : 19°C to 26°C

- Humidity in the air : 45% to 65% RH

- Maximum accoustic pressure in the room during use : 40 to 48 dBA

High risk of infection

- Particulate air cleanliness classification : ISO 7 (less than 352,000 particles of 0.5 microns per m³ of air

- Particle elimination classification of 0.5 microns : CP10

- Microbiological cleanliness classification M10

Air treatment equipment

- STERIBLOC unit – Filtration F6 + F7 + F9 (in conformity with standard EN 1886)

- Distribution of treated air via filtering casings

- Unidirectional or non-unidirectional air flow

- H14 finishing filters for the treated zone

- Rate of air turnover : more than or equal to 15 vol/h

- Fresh air renewal in the room : 6 vol/h

- Pressurisation of the room : 15 Pa (differential fresh air / recycled air)

- Air temperature (except for specific requirements) : 19°C to 26°C

- Humidity in the air : 45% to 65% RH

- Maximum accoustic pressure in the room during use : 40 to 48 dBA

Moderate risk of infection

- Particulate air cleanliness classification : ISO 8 (less than 3,520,000 particles of 0.5 microns per m³ of air

- Particle elimination classification of 0.5 microns : CP20

- Microbiological cleanliness classification M100

Air treatment equipment

- STERIBLOC unit – Filtration F6 + F7 + H13 (in conformity with standard EN 1886)

- Distribution of treated air via diffusion vents, induction grills

- No finishing filters in the treated zone

- Rate of air turnover : more than or equal to 10 vol/h

- Fresh air renewal in the room : 6 vol/h

- Pressurisation of the room : 15 Pa (differential fresh air / recycled air)

- Air temperature (except for specific requirements) : 19°C to 26°C

- Humidity in the air : 45% to 65% RH

- Maximum accoustic pressure in the room during use : 40 to 48 dBA

- Level 4 Risk Zones - ISO 5

- Level 3 Risk Zone - ISO 7

- Level 2 Risk Zone - ISO 8

Very high risk of infection

- Particulate air cleanliness classification : ISO 5 (less than 100,000 particles of 0.1 micron per m³ of air)

- Particle elimination classification of 0.5 microns : CP5

- Microbiological cleanliness classification M1

Air treatment equipment

- STERIBLOC unit – Filtration F6 + F7 + F9 (in conformity with standard EN 1886)

- Distribution of treated air via filtering ceiling units

- Unidirectional air flow

- H14 finishing filters for the treated zone

- Rate of air turnover : depending on sizing of filtering ceiling unit

- Fresh air renewal in the room : 6 vol/h

- Pressurisation of the room : 15 Pa (differential fresh air / recycled air)

- Air temperature (except for specific requirements) : 19°C to 26°C

- Humidity in the air : 45% to 65% RH

- Maximum accoustic pressure in the room during use : 40 to 48 dBA

High risk of infection

- Particulate air cleanliness classification : ISO 7 (less than 352,000 particles of 0.5 microns per m³ of air

- Particle elimination classification of 0.5 microns : CP10

- Microbiological cleanliness classification M10

Air treatment equipment

- STERIBLOC unit – Filtration F6 + F7 + F9 (in conformity with standard EN 1886)

- Distribution of treated air via filtering casings

- Unidirectional or non-unidirectional air flow

- H14 finishing filters for the treated zone

- Rate of air turnover : more than or equal to 15 vol/h

- Fresh air renewal in the room : 6 vol/h

- Pressurisation of the room : 15 Pa (differential fresh air / recycled air)

- Air temperature (except for specific requirements) : 19°C to 26°C

- Humidity in the air : 45% to 65% RH

- Maximum accoustic pressure in the room during use : 40 to 48 dBA

Moderate risk of infection

- Particulate air cleanliness classification : ISO 8 (less than 3,520,000 particles of 0.5 microns per m³ of air

- Particle elimination classification of 0.5 microns : CP20

- Microbiological cleanliness classification M100

Air treatment equipment

- STERIBLOC unit – Filtration F6 + F7 + H13 (in conformity with standard EN 1886)

- Distribution of treated air via diffusion vents, induction grills

- No finishing filters in the treated zone

- Rate of air turnover : more than or equal to 10 vol/h

- Fresh air renewal in the room : 6 vol/h

- Pressurisation of the room : 15 Pa (differential fresh air / recycled air)

- Air temperature (except for specific requirements) : 19°C to 26°C

- Humidity in the air : 45% to 65% RH

- Maximum accoustic pressure in the room during use : 40 to 48 dBA

Download the brochure

ISO 9001:2015

Design, manufacture, starting-up and after-sales service of equipments for precision air and thermic treatment

ISO 14644

Clean rooms and related controlled environments

ISO 14644 establishes the classification of levels of cleanliness of solid surfaces by concentration of particles, applicable to clean rooms and related controlled environments.

ISO 14644 applies to all the solid surfaces in clean rooms and related controlled environments such as walls, ceilings, floors, work environments, tools, equipment and products. The classification of the cleanliness of the surfaces by concentration of particles (SCP) is limited to particles sized between 0.05 μm and 500 μm.

GMP

“Good Manufacturing Practice” in the Pharmaceutical Industry

GMP is good manufacturing practice in the European Pharmaceutical industry (in French BPF : Bonnes Pratiques de Fabrication).

Concerning air quality, this defines classes A to D, which determine the number of particles permitted depending on the zone to be protected.

It also introduces a notion of airborne bacteriological contamination which does not appear in the other standards.